Advanced Manufacturing Engineering

AdvME, with Tom Doney as a Technical Lead, can help CPG packaging companies of any size start their smart manufacturing journey. Then, if needed, AdvME can also lead and assist in areas identified for improvement in filling, packing, and inspection/data collection technologies.

Tom Doney

Technical Lead

Over 30 years in the Food & Beverage Industry in packaging machinery and systems development and deployment for the two largest global F&B companies.

Prior to forming AdvME, he participated in developing a digital transformation strategy for packaging end of line operations as an Expert Engineer.

Multiple Roles in the OMAC Packaging Workgroup.

See Resume for further information

CESMII Certified Smart Manufacturing Roadmap Professional

AdvME’s Core Competencies

01 - In developing a packaging line it is important to analyze line flow and size the unit operations and the conveying system so that the filler is the bottleneck. When trying to restore rated throughput to an existing line, it is important to look at the line holistically.

02 - Unit operations must be properly maintained to sustain expected performance. A sudden deterioration in machine effectiveness may be due to a change in packaging material.

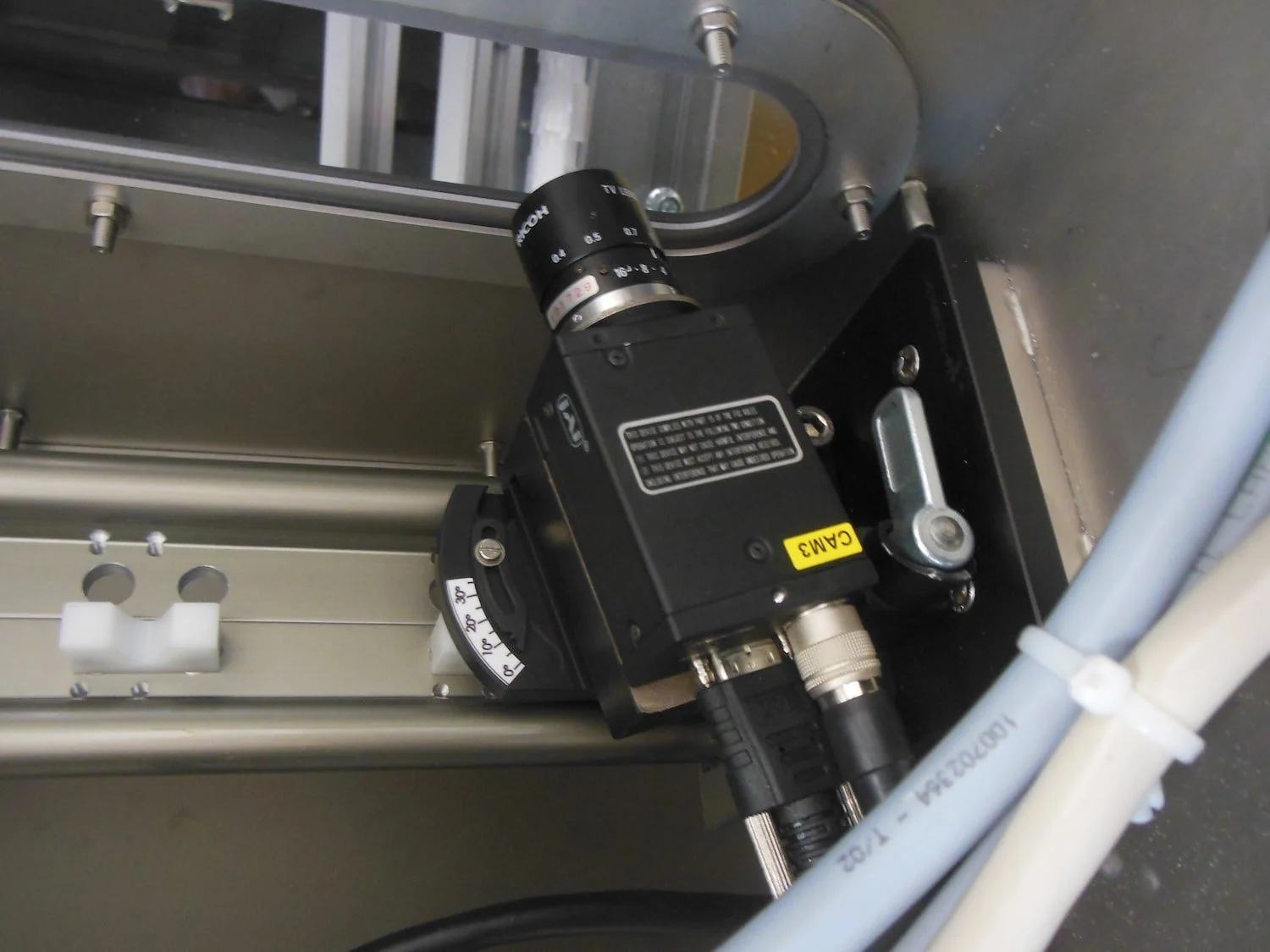

03 - Computer vision systems were the original Industry 4.0 sensor. In addition to pass/fail inspection decisions, vision systems can create trend charts that can flag a process drifting toward making defective parts.

04 - Smart sensors can now perform online analyses that were only possible before with a vision system.

05 - Robotic or Cobotic executions in unit operations can reduce re-tooling time when a change in line functionality is needed by the business.

Line Flow Analysis

What size of line surge can provide the best efficiency improvement?

Improve Unit Operation Performance

Case Packing

Are cases sized properly?

Is corrugate in best condition for correct feeding, folding, gluing?

Video Systems

High speed inspections of package characteristics – provide pass/fail plus process measurement data

Smart Sensors

Small Footprint, High Speed

Can provide pass/fail decisions

PLUS

Ongoing data stream of measurements for part/assembly trends or event recording

Robot or Cobot?

Robots enable tool less changeover for different cases sizes and pallet patterns. In a slower application (for manual pallet stacking automation), a cobot could suffice.